Characteristics of Titanium Alloys

Submitted by admin on 01/27/2014

Because of high intensity, mechanical properties and excellent corrosion resistance, titanium alloys become ideal manufacturing materials for aircraft and engines. But the cutting and machining performance of titanium alloys are poor, which restrict titanium alloys’ applications to a great degree for a long period of time.

In recent years, with the development of processing technology, titanium alloys are widely applied in the manufacture of air-compressor, engine cover, air exhausting device and other components of aeroplance engine and the production of beam frame and other structural frames of aircraft.

Compared with general alloy steel, titanium alloys possess the following advantages:

1. High specific strength

2. Excellent mechanical performance. The melting point of titanium alloys is 1660 ℃, which is higher than that of iron. At the same time, titanium alloys possess higher heat intensity and can work under 550 ℃, at the same time, titanium alloys usually display better toughness at low temperature.

3. Good corrosion resistance. Under 550 ℃, the surface of titanium alloys is easy to form dense oxide film, so titanium alloys are not easy to be further. Titanium alloys have great resistance to corrosion, like atmosphere, seawater, vapour and acid, alkali, salt medium.

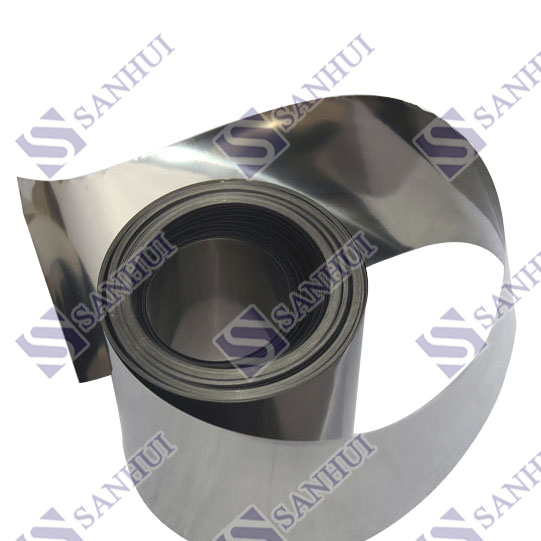

Titanium supplier in China-Zhengzhou Sanhui Co., Ltd can offer a wide range of titanium products, like titanium flanges, titanium foil and others.

You are welcome to visit us.