Classification

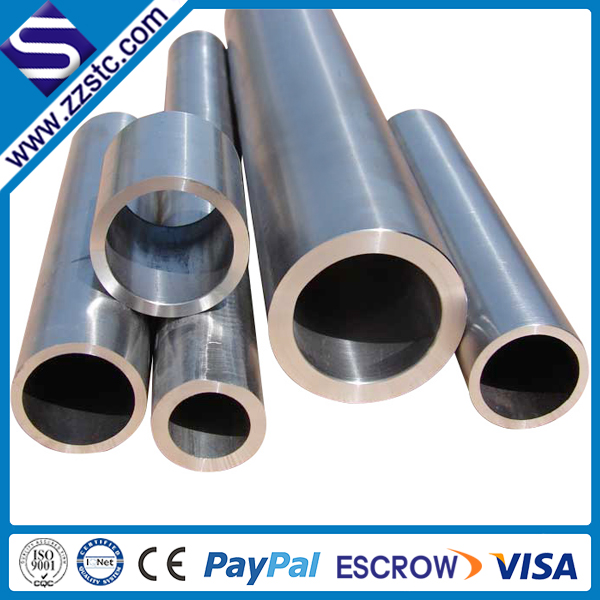

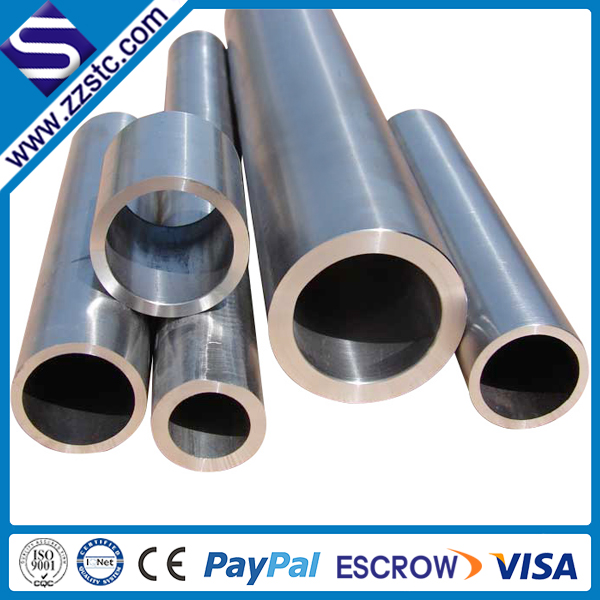

Two aspects to improve the welding of titanium tube

Submitted by admin on 11/10/2015

There are a lot of welding methods for titanium tube, the most common one is the use of inert gas protection, there are also some ion welding, spot welding, brazing, etc. In order to improve the quality of titanium pipe welding, two points is needed to pay special attention to in the following.

1. The effect of gap elements: In the process of welding, oil, residual oil, and other factors, such as the cylinder, cotton yarn will cause the rise of the intensity and the drop of the plastic. The main reason of producing the porosity of welds in titanium pipe is that the gas and gas flow in the welding pool are involved,

2. The thick grains and the formation of metastable organization: titanium and titanium tube have high melting point and poor thermal conductivity, welding and heat affected zone is higher than the critical point for a long time, which can cause coarse grains in two parts and the lower plasticity of welded joint.

Based on the two points in the above, before welding, we should rigorously clean the artifacts, filler wire, jigs, fixtures and equipment, in order to prevent the pollution when welding and reduce the harm of gap elements.

1. The effect of gap elements: In the process of welding, oil, residual oil, and other factors, such as the cylinder, cotton yarn will cause the rise of the intensity and the drop of the plastic. The main reason of producing the porosity of welds in titanium pipe is that the gas and gas flow in the welding pool are involved,

2. The thick grains and the formation of metastable organization: titanium and titanium tube have high melting point and poor thermal conductivity, welding and heat affected zone is higher than the critical point for a long time, which can cause coarse grains in two parts and the lower plasticity of welded joint.

Based on the two points in the above, before welding, we should rigorously clean the artifacts, filler wire, jigs, fixtures and equipment, in order to prevent the pollution when welding and reduce the harm of gap elements.

------分隔线----------------------------